Friday, 28 March 2014

Torque Converter

Operation :

Fluid sent to the torque converter from the transmission oil pump is picked up by the rotating vanes of the impeller and transferred to the turbine vanes through rotary and vortex flow paths.

The impeller, also known as the pump, is the driving member and rotates with the engine. The impeller vanes pick up fluid in the converter housing and direct it toward the turbine. Fluid flow drives the turbine, and when the flow between the impeller and turbine is adequate, the turbine rotates and turns the transmission input shaft. A torque converter contains the stator, or reactor, a reaction member mounted on a one-way clutch. The vanes used in each of the three elements of a torque converter are curved to increase the diversion angle of the fluid. This also increases the force exerted by the fluid and improves the hydraulic advantage.

The outlet side of the impeller vanes accelerates the fluid as it leaves the impeller to increase torque transfer to the turbine.

. The inlet side of the turbine vanes absorb shock and limit power loss that occurs when flow between the impeller and turbine suddenly changes. The curve of the stator vanes is opposite to the curve of the impeller and turbine vanes

. Since the stator is located between the impeller and turbine, it adds to the original impeller flow and multiplies the force delivered to the turbine.

Fluid sent to the torque converter from the transmission oil pump is picked up by the rotating vanes of the impeller and transferred to the turbine vanes through rotary and vortex flow paths.

The impeller, also known as the pump, is the driving member and rotates with the engine. The impeller vanes pick up fluid in the converter housing and direct it toward the turbine. Fluid flow drives the turbine, and when the flow between the impeller and turbine is adequate, the turbine rotates and turns the transmission input shaft. A torque converter contains the stator, or reactor, a reaction member mounted on a one-way clutch. The vanes used in each of the three elements of a torque converter are curved to increase the diversion angle of the fluid. This also increases the force exerted by the fluid and improves the hydraulic advantage.

The outlet side of the impeller vanes accelerates the fluid as it leaves the impeller to increase torque transfer to the turbine.

. The inlet side of the turbine vanes absorb shock and limit power loss that occurs when flow between the impeller and turbine suddenly changes. The curve of the stator vanes is opposite to the curve of the impeller and turbine vanes

. Since the stator is located between the impeller and turbine, it adds to the original impeller flow and multiplies the force delivered to the turbine.

LEAF SPRING

A leaf spring is a simple type of suspension spring commonly used in vehicles. This type of spring is typically constructed of one or more flat, thin, flexible steel strips that are joined together in order to work as a single unit. The steel strips of a leaf spring are curved into an arc and attached at each end to the underside of a vehicle to help position and support the axle, and also to absorb shock.

SUPERCHARGER

A supercharger is an air compressor that increases the pressure or density of air supplied to an internal combustion engine.

This gives each cycle of the engine more oxygen, letting it burn more fuel and do more work, thus increasing power.

Power for the supercharger can be provided mechanically by means of a belt, gear, shaft, or chain connected to the engine's crankshaft.

This gives each cycle of the engine more oxygen, letting it burn more fuel and do more work, thus increasing power.

Power for the supercharger can be provided mechanically by means of a belt, gear, shaft, or chain connected to the engine's crankshaft.

Tuesday, 25 March 2014

Difference between Flywheel and Governor

The function of flywheel is to store the energy/power produced during the power stroke of an engine and this stored energy is used during remaining stroke to make piston up and down during working of engine while governor tries control the speed of an engine due to variation in load. It does this work by reducing or increasing the amount of fuel passing to the engine.

& fig is given below

& fig is given below

COMBUSTION

Combustion or burning is the sequence of exothermic chemical reactions between a fuel and an oxidant that is carried out by production of heat and conversion of chemical species.

The release of heat can produce light in the form of either glowing or a flame.

There are basically two types of combustion:-

Complete combustion

Incomplete combustion.

Rapid combustion

Turbulent combustion

Micro combustion

Stoichiometric combustion

1.Complete combustion:-

In a complete combustion reaction, a compound reacts with an oxidizing element, such as oxygen or fluorine, and the products are compounds of each element in the fuel with the oxidizing element. For example:

CH4 + 2 O2 ? CO2 + 2 H2O + energy

A simple example can be seen in the combustion of hydrogen and oxygen, which is a commonly used reaction in rocket engines:

2 H2 + O2 ? 2 H2O(g) + heat

The result is water vapor.

2.Incomplete combustion:-

In a incomplete combustion it will only occur when there is not enough oxygen to allow the fuel to react completely to produce carbon dioxide and water. It also happens when the combustion is quenched by a heat sink such as a solid surface or flame trap.

3.Rapid combustion:-

Container of ethanol vapour mixed with air, undergoing rapid combustion.Rapid combustion is a form of combustion, otherwise known as a fire, in which large amounts of heat and light energy are released, which often results in a flame. This is used mainly in a form of machinery such as internal combustion engines and in thermobaric weapons.

4.Turbulent combustion:-

Turbulent Combustion is that type of combustion that resulting in a turbulent flame is the most used for industrial application (e.g. gas turbines, gasoline engines, etc.) because the turbulence helps the mixing process between the fuel and oxidizer.

5.Micro combustion:-

It is a processes which happen in very small volumes are considered micro-combustion. The high surface-to-volume ratio increases specific heat loss. Quenching distance plays a vital role in stabilizing the flame in such combustion chambers.

6.Stoichiometric combustion:-

Stoichiometric combustion of a hydrocarbon in oxygen is Generally, the chemical equation for stoichiometric combustion of a hydrocarbon in oxygen is:For example, the stoichiometric burning of propane in oxygen is:Stoichiometric combustion of a hydrocarbon in air is the stoichiometric combustion takes place using air as the oxygen source, the nitrogen present in the air can be added to the equation (although it does not react) to show the composition of the resultant flue gas.

The release of heat can produce light in the form of either glowing or a flame.

There are basically two types of combustion:-

Complete combustion

Incomplete combustion.

Rapid combustion

Turbulent combustion

Micro combustion

Stoichiometric combustion

1.Complete combustion:-

In a complete combustion reaction, a compound reacts with an oxidizing element, such as oxygen or fluorine, and the products are compounds of each element in the fuel with the oxidizing element. For example:

CH4 + 2 O2 ? CO2 + 2 H2O + energy

A simple example can be seen in the combustion of hydrogen and oxygen, which is a commonly used reaction in rocket engines:

2 H2 + O2 ? 2 H2O(g) + heat

The result is water vapor.

2.Incomplete combustion:-

In a incomplete combustion it will only occur when there is not enough oxygen to allow the fuel to react completely to produce carbon dioxide and water. It also happens when the combustion is quenched by a heat sink such as a solid surface or flame trap.

3.Rapid combustion:-

Container of ethanol vapour mixed with air, undergoing rapid combustion.Rapid combustion is a form of combustion, otherwise known as a fire, in which large amounts of heat and light energy are released, which often results in a flame. This is used mainly in a form of machinery such as internal combustion engines and in thermobaric weapons.

4.Turbulent combustion:-

Turbulent Combustion is that type of combustion that resulting in a turbulent flame is the most used for industrial application (e.g. gas turbines, gasoline engines, etc.) because the turbulence helps the mixing process between the fuel and oxidizer.

5.Micro combustion:-

It is a processes which happen in very small volumes are considered micro-combustion. The high surface-to-volume ratio increases specific heat loss. Quenching distance plays a vital role in stabilizing the flame in such combustion chambers.

6.Stoichiometric combustion:-

Stoichiometric combustion of a hydrocarbon in oxygen is Generally, the chemical equation for stoichiometric combustion of a hydrocarbon in oxygen is:For example, the stoichiometric burning of propane in oxygen is:Stoichiometric combustion of a hydrocarbon in air is the stoichiometric combustion takes place using air as the oxygen source, the nitrogen present in the air can be added to the equation (although it does not react) to show the composition of the resultant flue gas.

Power Steering

Power steering helps drivers steer vehicles by augmenting steering effort of the steering wheel. Hydraulic or electric actuators add controlled energy to the steering mechanism, so the driver needs to provide only modest effort regardless of conditions. Power steering helps considerably when a vehicle is stopped or moving slowly. Also, power steering provides some feedback of forces acting on the front wheels to give an ongoing sense of how the wheels are interacting with the road; this is typically called "rοad feel".

Hydraulic Brake

ethylene glycol) to transfer the pressure applied

by the operator from the controlling unit to the

actual brake mechanism, which is usually at or

near the wheel of the vehicle.

•Most vehicles in India prefer to have drum

brakes on rear wheels while disk brakes on the

front wheels attached to the hydraulic

controlling unit.

by the operator from the controlling unit to the

actual brake mechanism, which is usually at or

near the wheel of the vehicle.

•Most vehicles in India prefer to have drum

brakes on rear wheels while disk brakes on the

front wheels attached to the hydraulic

controlling unit.

What is the difference between Jigs & fixtures

In metalworking and woodworking, both jigs and fixtures are essential tools. They are often confused with each other; however, they are two different tools with different functions. A jig is a type of tool that is used to control the location and/or motion of another tool. A fixture, on the other hand, is a work-holding or support device, used to hold the work in place.

3D Modeling with Hand Gestures

Recently, Elon Musk described how SpaceX has integrated SiemensNX, software his company uses to design rockets, and Leap Motion, software that turns gestures into computer commands, allowing engineers to more naturally and easily design products. Another combination of programs in widespread use in 3D modeling is “Shape-It-Up” and “Kinect.”

Technology that has made 3D design and modeling possible includes: recognition of symmetric and asymmetric 3-D shapes, Hidden Markov Models (HMM) for recognition of input patterns, “parallel-pipelined” computer algorithms, depth sensing cameras, speech recognition, eye tracking and others which we will look at in future IndustryTap articles.

Engineers report 3-D modeling via gestures allows molding and manipulation of virtual materials as if modeling with clay; 3D designs can be printed on 3D printers in a matter of minutes, speeding up the development process. A team at Purdue University, which has been developing this technology, believes video game developers, design engineers and architects will benefit the most.

Technology that has made 3D design and modeling possible includes: recognition of symmetric and asymmetric 3-D shapes, Hidden Markov Models (HMM) for recognition of input patterns, “parallel-pipelined” computer algorithms, depth sensing cameras, speech recognition, eye tracking and others which we will look at in future IndustryTap articles.

Engineers report 3-D modeling via gestures allows molding and manipulation of virtual materials as if modeling with clay; 3D designs can be printed on 3D printers in a matter of minutes, speeding up the development process. A team at Purdue University, which has been developing this technology, believes video game developers, design engineers and architects will benefit the most.

Monday, 24 March 2014

Milling machine

Milling machines are very versatile. They are usually used to machine flat surfaces on square or rectangular parts, but

can also produce many unique and irregular surfaces. They can also be used to drill, bore, produce slots, pockets and

many other shapes. The type of milling machine in the UCR Mechanical Engineering Machine Shop is a variable speed

vertical spindle, knee-mill with a swiveling head (also known as a “Bridgeport”). Although there are several other types

of milling machines, this document will focus only on the vertical milling machine.

A milling machine removes metal by rotating a multi-toothed cutter that is fed into the moving workpiece. The spindle

can be fed up and down with a quill handle on the head.

can also produce many unique and irregular surfaces. They can also be used to drill, bore, produce slots, pockets and

many other shapes. The type of milling machine in the UCR Mechanical Engineering Machine Shop is a variable speed

vertical spindle, knee-mill with a swiveling head (also known as a “Bridgeport”). Although there are several other types

of milling machines, this document will focus only on the vertical milling machine.

A milling machine removes metal by rotating a multi-toothed cutter that is fed into the moving workpiece. The spindle

can be fed up and down with a quill handle on the head.

The goal of this SOP and the accompanying “training” is not to make you a mill operator/machinist, but to make sure

you can safely do certain tasks. It applies to all students, staff, faculty and others who wish to use the machine shop!

This SOP should be read, fully understood, and reviewed at the machine with the Shop Manager. Every machine user will

have to take the “Basic User Safety Test”, demonstrate “hands-on” proficiency and then sign the “BASIC USER

CLEARANCE FORM & SUPERVISED EXPERIENCE LOG” before being approved to operate the machine. The allowable

machining tasks will be limited to those covered in this SOP.

There is much more to using a mill than what is covered in this SOP. Always ask before doing a new operation!

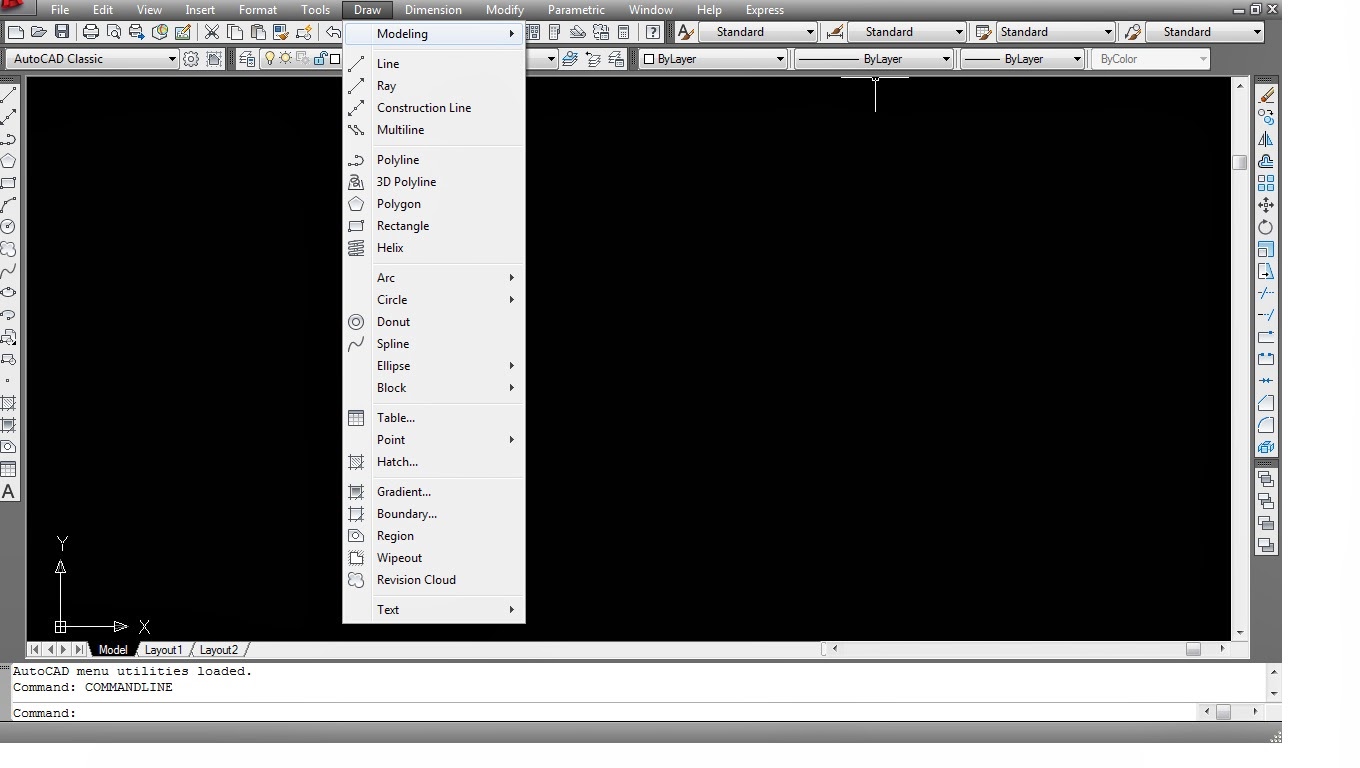

Autocad

AutoCAD is a software application for 2D and 3D computer-aided design (CAD) and drafting — available since 1982 as a desktop application and since 2010 as a mobile web- and cloud-based app, currently marketed as AutoCAD 360.

Developed and marketed by Autodesk, Inc.,[2] AutoCAD was first released in December 1982 — having been purchased a year prior in its original form by Autodesk founder John Walker. The software is currently marketed in its eighteenth generation.

As Autodesk's flagship product, by March 1986 AutoCAD had become the most ubiquitous microcomputer design program worldwide, with functions such as "polylines" and "curve fitting".[3] Prior to the introduction of AutoCAD, most other CAD programs ran on mainframe computers or minicomputers, with each CAD operator (user) working at a graphical terminal or workstation.[citation needed]

AutoCAD is used across a range of industries, including architects, project managers and engineers, among other professions, with 750 training centers established worldwide as of 1994.

Lathe Mechine

Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, parts reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two centers, at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck orcollet, or to a faceplate, using clamps or dogs.

Examples of objects that can be produced on a lathe include candlestick holders, gun barrels, cue sticks, table legs, bowls, baseball bats, musical instruments (especially woodwind instruments), crankshafts, and camshafts.

Subscribe to:

Comments (Atom)